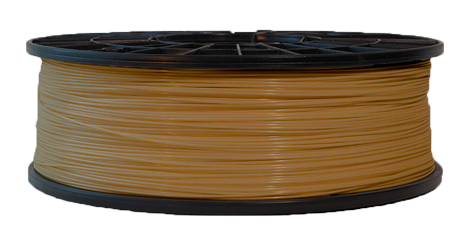

Ultem 1010 FDM Thermoplastic

Ultem 1010 material properties

Ultem 1010 is a high-performance thermoplastic material that is particularly well-suited for 3D printing applications requiring high strength, durability, thermal stability and flame retardancy.

This polyetherimide (PEI) resin is known for its high heat resistance and the lowest coefficient of thermal expansion among all FDM materials, which allows the material to withstand temperatures up to 216°C without degrading or losing its structural integrity. Ultem 1010 is often used for creating end-use parts for high-temperature applications, such as aerospace and automotive industries. Additionally, Ultem 1010 is highly durable and impact-resistant, making it an ideal choice for parts that need to withstand harsh environments and rough handling. The material also offers excellent electrical insulation, chemical resistance, and dimensional stability, ensuring that printed parts remain accurate and consistent over time. Another benefit of Ultem 1010 is its flame retardancy, which makes it suitable for use in applications that require compliance with strict safety standards, including aerospace, transportation, and electronics.

Good to know

You can save up to 50% with our FDM materials compared to the OEM!

Ultem 1010 Applications

Prototyping

Tool Manufacturing

Mass Production

Contact us to find the best material for your application

Did you know?

Ultem 1010 is the strongest FDM material and therefore ideal for demanding applications. The material is often used in the automotive and aerospace industries.